Six Key Factors Influencing the Rebound Performance of Polyurethane Flexible Foam

Polyurethane flexible foam has gained widespread application for its exceptional rebound performance, whether in furniture cushioning, car seats, or sports equipment. So, what factors influence its rebound performance? Let's have a look.

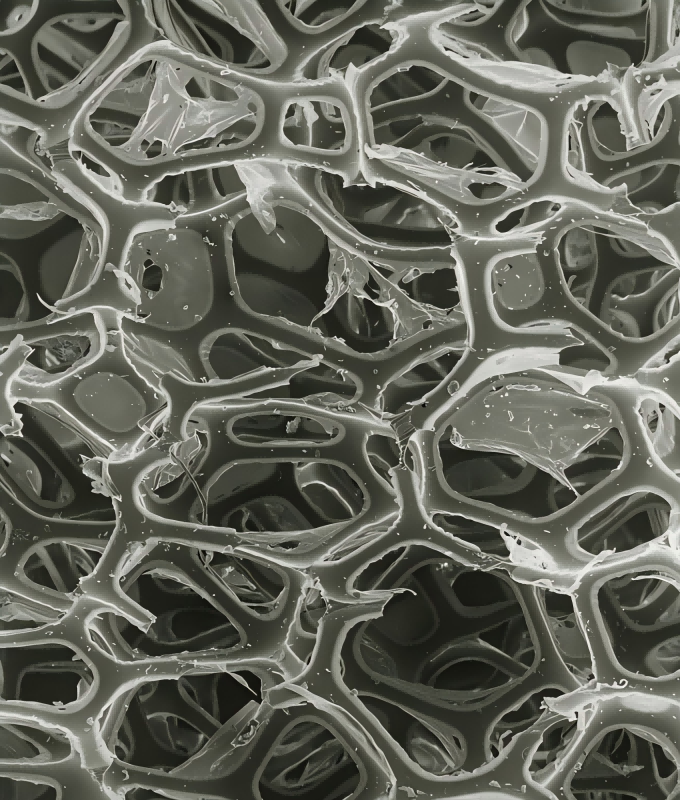

1: Cell Openness

Firstly, cell openness is a crucial aspect that determines the rebound performance of polyurethane foam. Imagine if the cells in the foam were all "open-mouthed," the polymer can distribute more freely, naturally the rebound performance can be better. Conversely, if the cell walls are overly closed, the foam will become stiff. Therefore, by adjusting the amount of blowing agent and optimizing the surface tension of the cell walls, we can make the cells easier to "open," thereby enhancing the foam's rebound performance.

2: Cell Shape

The shape of the cells is also key. A regular, spherical cell structure acts like tiny springs, effectively resisting external forces and maintaining shape, giving the foam excellent rebound performance. In contrast, needle-like or irregular cells are prone to collapse, affecting overall performance. Lowering the foaming temperature to avoid excessive cell expansion and deformation is a good method for maintaining regular cell shape.

3: Cell Size and Distribution

In the world of foam, the size and distribution of cells are also an important factor. An appropriate number of small cells can increase the density and rebound rate of the foam, but smaller is not always better; finding the "golden ratio" is crucial. Additionally, a higher cell density leads to better rebound performance. The addition of cell stabilizers helps achieve a reasonable distribution of cell sizes, further enhancing rebound performance.

4: Selection of Polyol

The choice of raw materials cannot be overlooked. The relative molecular weight of polyol directly affects the flexibility of the foam's molecular chains and its rebound performance. Within a certain range, a higher molecular weight leads to better rebound performance. However, excessively high molecular weights can also result in decreased hardness. Therefore, when using high-molecular-weight polyol, adding antioxidants to prevent degradation is an important measure to maintain stable foam performance.

5: Precise Control of Isocyanates

When it comes to isocyanates, particularly TDI (toluene diisocyanate), its usage directly correlates with the foam's hardness and rebound performance. Within an appropriate range, increasing the TDI index can significantly enhance the foam's hardness and rebound performance. But too much of a good thing can be detrimental, and precise control is essential.

6: Fine-Tuning the Formula for Optimal Performance

Finally, some subtle adjustments can also have a significant impact on foam performance. For example, adjusting the mass ratio of water to polyol can improve the foam's rebound performance to a certain extent; while reducing the amount of chain extender can maintain tensile strength while avoiding a decrease in rebound performance. By finely adjusting these parameters, we can keep the foam's rebound performance in optimal condition.

What other factors can affect the rebound performance of polyurethane flexible foam ? Welcome to discuss.