A brief introduction to flexible polyurethane foam

Flexible polyurethane foam is a polymer produced from the reaction of polyols and isocyanates. It is characterized by a cellular structure with low density, good elastic recovery, sound absorption, air permeability, heat preservation and other properties.

It’s widely used in furniture, bedding, automotive seating, athletic equipment, packaging, footwear and carpet cushion. It also plays a important role in soundproofing, filtration and shockproof.

The raw materials to make flexible polyurethane foam include polyols, diisocyanates, blowing agent,surfactant,catalyst,flame retardant,and other additives.

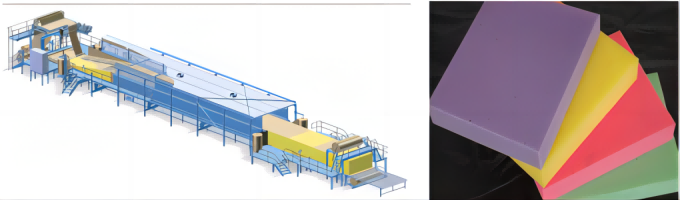

Flexible polyurethane foams can be classified as slabstock and molded foam based on the production process. The slabstock is produced by a continuous line where liquid chemicals are poured onto a conveyor belt and they immediately begin foaming and rise into a large bun. Then they’re cut and shaped into smaller pieces in a variety of sizes and configurations.

While, the molded foam is usually produced in a discontinuous process. This process involves pouring or injecting the liquid chemicals through a mixing head and into a preheated mold. The components react directly inside the mold to required shape. Molded foam is frequently found in auto interiors, business furniture and sports equipment.