Fire hazard and fire prevention measures of polyurethane foam

Foams made of polyurethane materials have superior insulation, thermal insulation and sound insulation properties. Polyurethane foam is a best-selling product widely used in production and life. The finished polyurethane foam is a porous solid with very poor thermal conductivity, which can easily cause heat accumulation and cause fires.

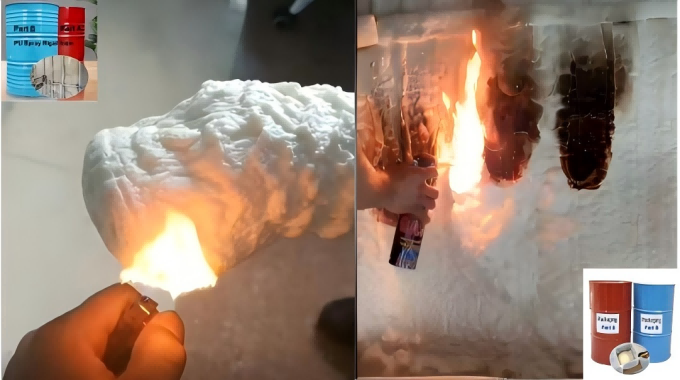

Fire characteristics

Polyurethane foam fires have different unique personalities compared to other combustible solid fires. The main performances are as follows:

1. The smoke is large and the toxicity is strong

When the polyurethane foam burns, it emits a large amount of black smoke. Because its smoke contains both decomposition and combustion products.

There are many combustion products of polyurethane foam, mainly CO, CO2, H2O, NO, NO2, NH3 and HCN. Among them, HCN is very toxic.

2. It is easy to produce smoldering

The smoldering of rigid polyurethane foam only occurs on the surface, and the maximum temperature of smoldering is about 500°C.

Flexible polyurethane foam can smolderer in still air at a maximum temperature of 400°C and can last for several hours.

3. The combustion speed is extremely fast and the flame temperature is high

Because polyurethane foam has the property of rapid decomposition under the action of temperature. When the temperature of a variety of small molecule combustible gases decomposed reaches the ignition point and the concentration reaches the combustion limit, a deflagration will occur in a comprehensive and violent combustion, so that the combustion will enter a state of "deflagration".

Fire prevention measures

1. The quality of raw materials should be well controlled, and operation control should be strictly implemented.

Before use, the analysis and testing should be carried out in accordance with the required standards, especially the water content and flammability and low molecular weight indicators of polyether polyols should be strictly controlled. In the operation, it is necessary to operate in strict accordance with the specified process conditions such as feeding ratio, sequence, mixing time and polymerization temperature.

2. Carry out flame retardant treatment to reduce the fire risk.

Inert gas is used to start the cannon, flame retardants are added, and inorganic salts can also be added to the foam to prevent smoldering in storage.

3. Reasonable use to reduce fire hazards.

Polyurethane foam with smoldering and spontaneous combustion characteristics is not suitable for thermal insulation of fire hazard production equipment and interior decoration of aircraft, ships, vehicles and buildings.

4. Improve the process and develop flame-retardant foam plastics.

It is necessary to overcome the imperfections of the current production process and equipment, strengthen the research on the best ratio, the best polymerization conditions and the best mixing method, and reform the process and equipment to make it reliable in control and safe and simple in operation.

Polyurethane foam fires are frequent fires that cause great harm, great losses and are difficult to extinguish. Therefore, we should increase the research and development of flame retardant and flame retardant new polyurethane foams.

Qichen has been committed to the research and production of rigid and flexible polyurethane foam raw materials with excellent flame retardancy, and the raw materials prepared at present can reach B1 flame retardant grade, which is difficult to ignite and B2 flame retardant grade is self-extinguishing from fire.