Effect of TDI acidity on the production of polyurethane flexible foam

In the actual production process of polyurethane flexible foam, there are often various quality problems in the products, and there are many causes for these problems. Sometimes, the problem cannot be solved well after multiple investigations, but few people notice that it may be due to the high acidity of TDI.

The effect of TDI acidity on foaming time is theoretically the effect on the chemical reaction of polyurethane. Most of the chemical reactions of polyurethane are carried out with the cooperation of various additives such as catalysts and cross-linking agents, and these chemical reactions are related to the acidity and alkalinity in the reaction system. The acidic medium is conducive to the chain expansion reaction to generate carbamate and urea; The alkaline substance promotes the branching cross-linking reaction to generate ureaformate, biuret and other groups.

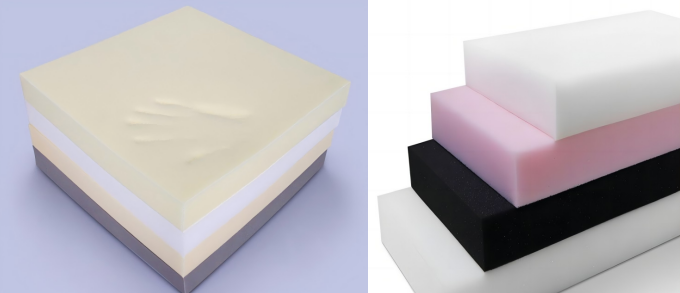

The effect of TDI acidity on the appearance of products:

There are two production methods of polyurethane flexible foam: box foaming and mechanical continuous foaming. The high acidity TDI for box foaming production foam will cause problems such as insufficient foaming, extended foaming time, insufficient bubble height, and extended non-stick time.

The effect of TDI acidity on the quality of products:

The bubble cells are coarse, uneven, poor hand feel, reduced rebound rate, and poor recovery of the product after vacuum compression. If the foaming process is too slow, there is a danger of collapse.

Solutions for problems with high acidity TDI foaming:

Reset the conveyor speed of the foaming machine;

Increase the amount of foam stabilizer and the speed of stirring;

It is best to do a small test before production.