A brief introduction to polyurethane sandwich panel (1)

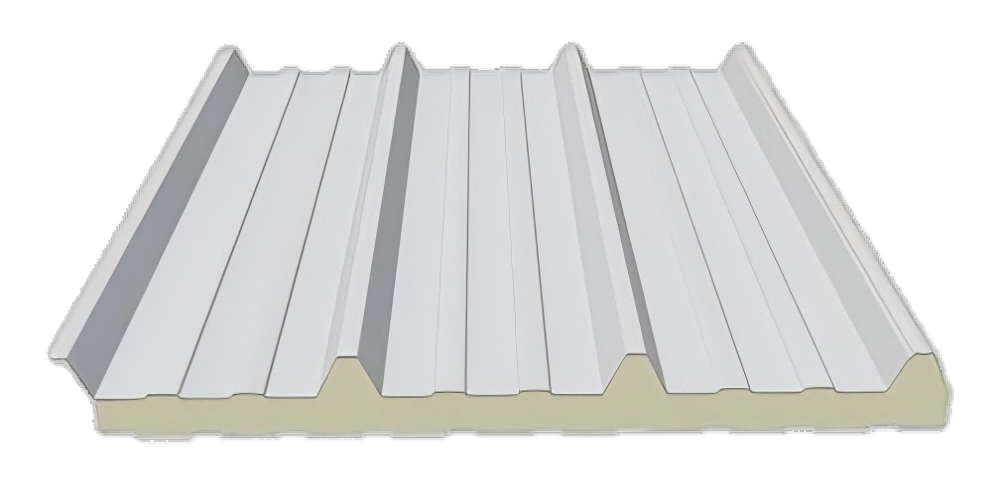

What is polyurethane sandwich panel ?

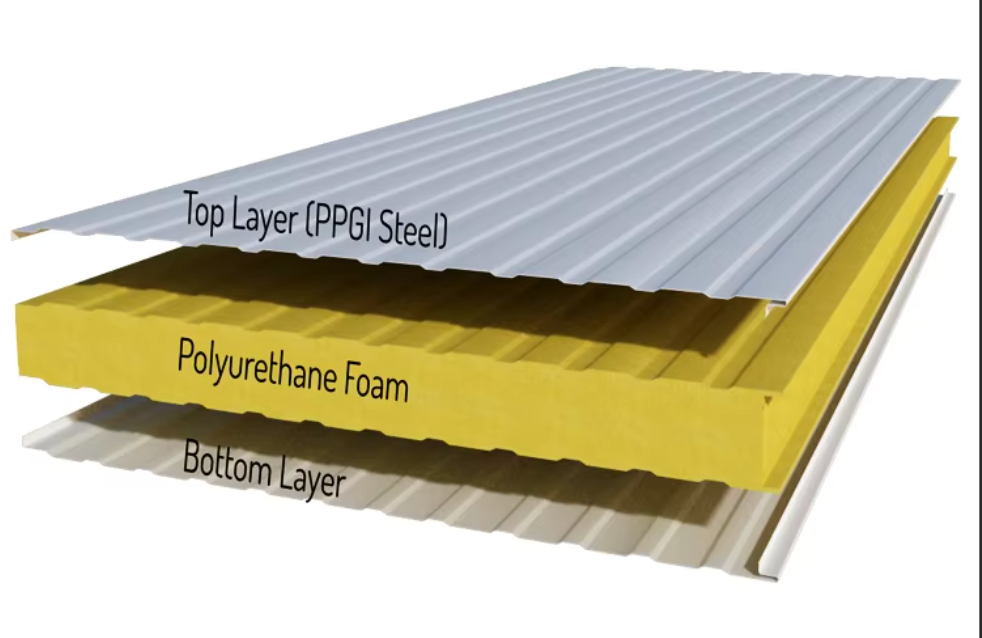

Polyurethane sandwich panel is a kind of high-performance building material primarily composed of three layers: two layers of high-strength metal sheets (such as color-coated steel plates, aluminum plates, etc.) serving as the face sheets, and a core material filled with rigid polyurethane foam. The polyurethane foam is injected between the two metal sheets through high-pressure foaming technology, forming a sturdy sandwich structure with exceptional insulation and thermal barrier properties.

How many kinds of polyurethane sandwich panels are there ?

There are indeed multiple ways to classify polyurethane sandwich panels, but the two primary classification methods are by core material and by application areas.

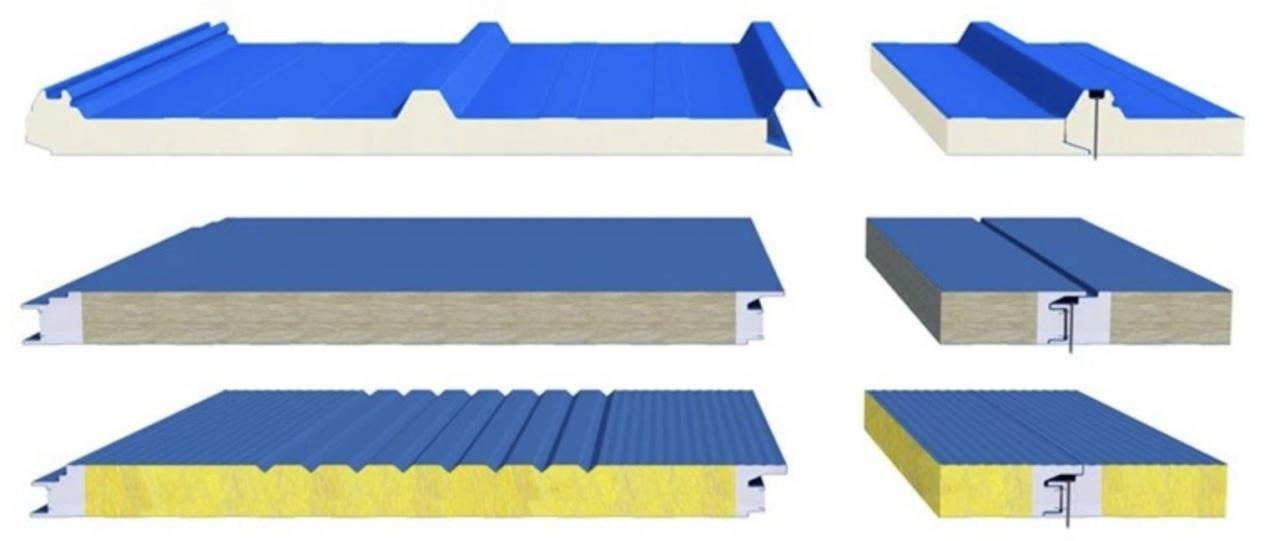

1: by Core Material:

a: Pure Polyurethane Sandwich Panel: This type of panel uses pure polyurethane rigid foam as the core material. It offers excellent insulation and thermal barrier properties due to the high-performance nature of polyurethane foam.

b: Polyurethane-Edged Glass Wool Sandwich Panel: In this variant, the core material is glass wool, which is encapsulated or edged with polyurethane rigid foam. Glass wool provides good insulation, and the polyurethane edges enhance the overall structural integrity and possibly add some additional insulation or moisture resistance.

c: Polyurethane-Edged Rock Wool Sandwich Panel: Similar to the glass wool version, this panel uses rock wool as the core material, with polyurethane edges. Rock wool is also an effective insulation material, and the polyurethane edges contribute to the panel's durability and performance.

2: by Application Areas

a: Roof Panel: Polyurethane sandwich panels designed specifically for use as roofing materials, offering superior insulation, weather resistance, and durability.

b: Wall Panel: Panels intended for use as wall materials, providing insulation, structural support, and aesthetic appeal in various building types.

c: Cold Storage Panel: Customized for use in cold storage facilities, these panels must maintain stable low temperatures and offer exceptional insulation to minimize energy loss.