Polyurethane green synthesis process: prepared from CO2 as raw material

Carbon dioxide is produced in large quantities as a by-product of many industrial processes, resulting in a sustained increase in atmospheric carbon dioxide concentrations above 420 ppm. This increase has raised serious concerns about climate change and prompted global efforts to mitigate its impacts.

Polymers are important in chemical products that can be produced from carbon dioxide. In contrast to fuels, which re-emit carbon dioxide immediately after combustion to obtain energy, polymers have a product life of up to several decades. Therefore, polymers containing carbon dioxide can effectively mitigate climate change by delaying the re-emission of carbon dioxide.

Polyurethane is one of the most versatile polymers. Given the strong interest in CO2-containing polymers, there have been several attempts to introduce CO2 into polyurethane as an alternative to fossil-based raw material. However, these efforts have focused on polyols, which are relatively easy to synthesize, and polyols are one of the monomers used in polyurethane synthesis. The synthesis of diisocyanate, another monomer of polyurethane, still relies on the traditional method of using phosgene, a highly toxic substance derived from petroleum resources. Therefore, the development of CO2-based diisocyanate synthesis technology is essential for the production of true CO2-based polyurethane.

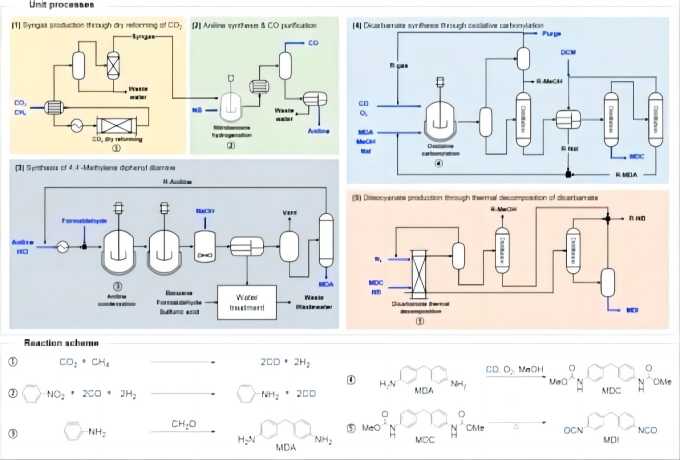

Researchers at the Korea Institute of Chemical Technology (KRICT) have proposed a sustainable process for synthesizing diphenylmethane diisocyanate (MDI). The process uses CO2 to produce synthesis gas, which is then separated by hydrogenation, oxidized carbonylation of the amine to form methyl 4,4'-diphenylmethane dicarbamate (MDC), and then thermal decomposition to produce MDI. Process modelling and life cycle assessment have shown significant environmental advantages over traditional MDI manufacturing processes, highlighting the potential of the technology as a more environmentally friendly alternative.