Efficient Recycling Methods for Polyurethane Waste

In recent years, polyurethane products have been widely used in areas such as refrigerator insulation layers, mattresses, and automotive components, and their environmentally friendly and recyclable characteristics are also highly valued.

Factories that produce polyurethane foam generate a large amount of offcuts, mold overflow, and waste products each year. At the same time, downstream applications, such as scrapped vehicles, also produce a significant amount of discarded polyurethane foam and elastomers. All of these wastes need to be properly managed. Here are some efficient recycling methods:

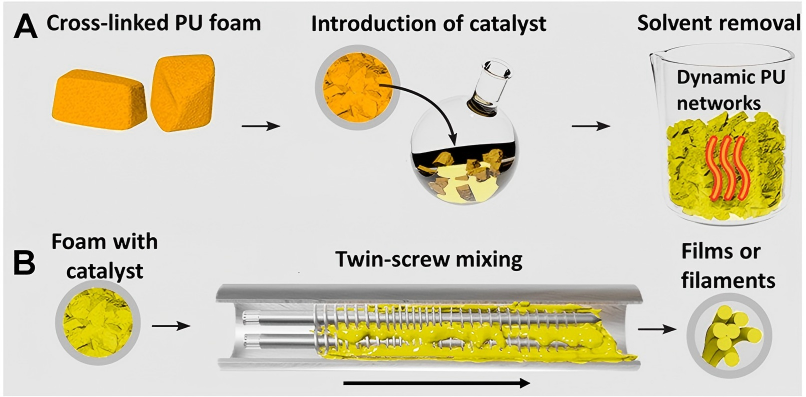

Physical Recycling

Physical recycling method has become an effective way to recycle polyurethane rigid foam and composite materials. By reducing the particle size of polyurethane foam products to meet secondary processing standards, waste materials or scraps from the production process can be transformed into more useful forms, such as flakes, granules, or powders, thereby achieving efficient recycling of polyurethane materials.

Adhesive molding technology

Adhesive molding technology is one of the most widely used processes in polyurethane recycling. The flexible polyurethane foam is crushed into small pieces using a crusher, and then mixed with reactive polyurethane adhesives in a mixer. Commonly used adhesives include polyurethane foam composites or NCO-terminated prepolymers based on polymethylene polyphenyl isocyanate (PAPI). During the mixing process, steam can be added to enhance the bonding effect. By adding an appropriate amount of recycled polyurethane and adhesive and mixing them thoroughly, dyes can be further added to change the color of the product. Afterwards, pressure is applied to the mixture to shape it.

Hot pressing molding method

Thermosetting polyurethane flexible foams and RIM polyurethane products exhibit a certain degree of thermoplasticity in the temperature range of 100-200°C. Under high-temperature and high-pressure conditions, these waste polyurethanes can bond to each other without the need for adhesives. To further improve the uniformity of recycled products, the waste material is usually ground first and then molded under heat and pressure.

Filler Application

Polyurethane flexible foam can be transformed into fine particles through low-temperature crushing or grinding. These particle dispersions can be combined with polyols and further used to manufacture polyurethane foam or other related products. This process not only achieves the recycling of waste polyurethane but also helps reduce the cost of new products.

Chemical recycling

Chemical recycling refers to the process of breaking down polyurethane foam into polyurethane raw materials or other basic chemical raw materials through chemical methods such as alcoholysis, aminolysis, hydrolysis, or pyrolysis.

Currently, polyurethane recycling in China is just beginning, and there is still big room for improvement compared to developed countries. Although the scrap generated during the production process of polyurethane is easy to recycle, the recycling and disposal of waste polyurethane materials after consumer use is not optimistic. So, China still needs to make more efforts in the field of polyurethane recycling.